- Home Page

- Company Profile

-

Our Products

- Floor Springs

- Patch Fittings

- Bottom Patch Fitting

- Quadruple Patch With Fin

- Top Pivot/Bottom Pivot for Wooden/Aluminium Doors

- Top Pivot for Patch Fittings Doors

- Top Patch Fitting

- Over Panel Side Panel Connecting(Small L)

- Glass to Glass Connecting Patch With Wall/Ceiling

- Over Panel Side Panel Patch Connector With Stopper

- Glass Door Stopper

- Corner Patch Lock With Strike Plate

- Double Over Panel Patch With Fin

- Over Panel Side Panel Connector With Fin (Left)

- Patch Lock Fitting

- Over Panel Side Panel Connecting Patch With Pivot(Big L)

- Double Over Panel Patch

- Wall Mounted Over Panel Patch With Pivot (Over Panel)

- Center Patch Lock

- Center Lock Strike Box

- Patch Lock

- Strick Box

- Quadruple Patch

- Wall To Glass Connecting Patch

- Over Panel Side Panel Connector With Fin(Right)

- Connector With Fin

- Mini Floor Hinge

- Triple Glass Patch Connector With Fin

- SHOWER HINGES (Premium Series)

- GLASS CONNECTORS (Premium Series)

- Glass Sliding Door Handle

- Steel Splice And Fin Plate

- Sliding Roller Fitting

- Sliding Door Fittings

- Glass Point Fitting

- Shower Brackets

- Spider Fittings

- Glass Door Handle

- Shower Knight Head Acessoriess

- Locks Without Cutout

- Office Sliding System

- Contact Us

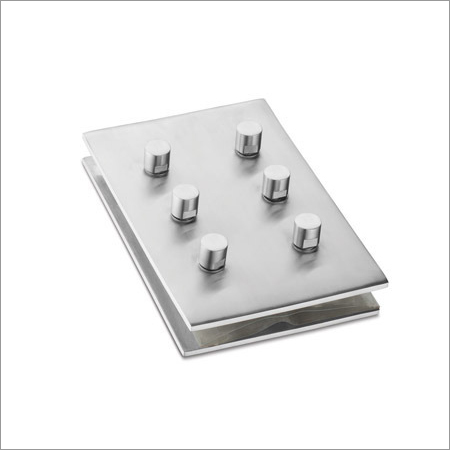

Stainless Steel Splice And Fin Plate

38.45 - 50.23 USD ($)/Piece

Product Details:

- Security Features Provides secure and stable glass fixing

- Anti Corrosion Yes, highly resistant due to stainless steel material

- Operating Temperature -20C to +80C

- Load Capacity Up to 300 kg (varies with model and installation)

- Standard Meets ASTM/EN standards for glazing hardware

- Usage & Applications Commercial buildings, malls, airports, office facades, glass canopies

- Glass Type Tempered/Laminated Glass compatible

- Click to View more

X

Stainless Steel Splice And Fin Plate Price And Quantity

- 1 Piece

- 38.45 - 50.23 USD ($)/Piece

Stainless Steel Splice And Fin Plate Product Specifications

- Commercial buildings, malls, airports, office facades, glass canopies

- Tempered/Laminated Glass compatible

- Meets ASTM/EN standards for glazing hardware

- Structural Glass Fitting

- Facade glazing, structural glass support, curtain wall assemblies, architectural fittings

- Manual/Fitted

- Satin/Brushed or Mirror Polished

- Bolted/Jointed Installation

- Flat/Rectangular Splice & Fin Plate

- Non-lockable mechanical joint

- Yes, highly resistant due to stainless steel material

- Provides secure and stable glass fixing

- -20C to +80C

- Splice & Fin Plate

- Frameless/Structural Glass Windows

- Silver

- Up to 300 kg (varies with model and installation)

- Wall or Structure Mounted

- Varies as per size and thickness (typically between 0.5 kg to 2.5 kg per piece)

- Stainless Steel (Grade 304/316 optional)

- High (specific value depends on SS grade typically 515 MPa for SS304)

- Compatible with 12 mm to 24 mm glass

- Depends on size and design, typically supports glass panels up to 300 kg

- Non-coated; can be PVD coated by request

- Brushed/Satin or Mirror Finish

- Standard sizes available (customization possible); example: 200 mm x 100 mm x 12 mm

- Connecting or joining glass panels and providing support

- Yes

Stainless Steel Splice And Fin Plate Trade Information

- 1000 Piece Per Day

- 5-6 Days

Product Description

Stainless Steel Splice And Fin Plate is extremely reliable and efficient to use ideal for different construction purposes. It is made using high grade materials tested by skilled professionals, acquired from reputed vendors. It has high degree of demand and is widely appreciated in the market for its features such as resistance against corrosion, dimensionally accuracy and fine-finish. Additionally, this Stainless Steel Splice And Fin Plate is offered in many specifications at most competitive prices.

Specifications:

- For: 10 / 12 mm glass

- Material: Stainless Steel

- Finish: Satin Stainless Steel (SSS)

Superior Corrosion and Weather Resistance

Manufactured from high-grade stainless steel, the splice and fin plate exhibits excellent defense against corrosion and harsh weather, making it ideal for both interior and exterior architectural uses. Its resilience ensures long-term functionality in diverse climatic conditions, minimizing replacement needs and maximizing safety for building facades.

Versatile Design and Custom Fabrication

Standard sizes are ready for immediate use, with options for custom dimensions to meet unique project requirements. Deburred edges enhance safety, and pre-drilled holes simplify installation. This flexibility, combined with custom fabrication services, supports innovative facade designs in commercial complexes, offices, malls, and airports.

FAQ's of Stainless Steel Splice And Fin Plate:

Q: How is the stainless steel splice and fin plate installed in glass facade systems?

A: Installation involves bolted or jointed mounting using the pre-drilled, countersunk or elongated holes, allowing secure attachment to walls or supporting structures. Proper alignment is ensured for optimal glass panel support.Q: What applications are best suited for this splice & fin plate?

A: These plates excel in facade glazing, structural glass supports for curtain walls, architectural fittings, frameless and structural glass windows, glass canopies, and are widely used in commercial buildings, malls, airports, and office facades.Q: When should I opt for custom fabrication for the splice and fin plate?

A: Custom fabrication is beneficial when project-specific dimensions, unique hole configurations, finishes, or additional performance features are required. Clients may submit drawings or specifications for tailored solutions.Q: Where does the product provide optimal performance regarding weather and corrosion resistance?

A: Its superior stainless steel composition ensures excellent resistance in humid, coastal, industrial, or harsh outdoor environments, as well as indoor applications, meeting global ASTM/EN standards for glazing hardware.Q: What are the recommended maintenance practices for these plates?

A: Routine cleaning with mild detergents is recommended to maintain appearance and corrosion resistance. The product requires minimal maintenance due to its robust material properties.Q: How does this plate benefit building security and glass installation safety?

A: With a high tensile strength (515 MPa for grade 304) and ability to support glass panels up to 300 kg, the plate delivers secure and stable glass fixation, minimizing risk during operation and usage.Q: Does the product require any coating for enhanced durability?

A: No additional coating is needed thanks to its inherent corrosion resistance. However, PVD coating can be applied upon request for specialized aesthetic or functional requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese